Slip Rings

Slip Ring Union

Rotary Unions

News Center

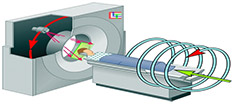

Slip Ring In The Spiral CT Machines

Electrical slip ring can be widely used in the CT machines, the details as follows:

1. Use of slip ring:

Slip ring is one of the important parts of spiral CT machines. It serves as a connection of the gantry rotating part and the fixed portion of the power line and the signal line. Thereby replacing conventional CT connection cable in the rotating parts, unidirectional scanning can quickly rotate, greatly improving the scanning speed, at the same time provide the basis for a helical scan.

2. The slip ring Category:

Slip ring points low pressure and high pressure slip ring.

3. The slip ring structure:

Slip ring is located on the back of the gantry rotating part, including 12 concentric metal rings components. Of which six are wide ring, as a power source is connected; six is fine ring, as a signal connection. The outer periphery of the slip ring is also equipped with a radio frequency transmission antenna for transmitting a data signal DAS. Brush plate is positioned in the right rear of the gantry.  There are two slip ring structures of Hispeed CT machine. One for SHDCD slip ring, the other for the RF slip ring, there are differences between the brush plate structure of these two slip rings, brush shapes, materials and quantities are different. Each conductive ring has a number of brushes with phase, which is to ensure good contact and reduce the voltage drop. SHDCD slip ring from the inside out, from 1 to 3 ring 480V power supply, each ring has nine carbon brushes phase; 4-5 ring is 115V power supply, each ring has 5 carbon brush contact; 6 ring is ground GND, There are six carbon brush phase; 7-8 is a trigger signal DAS. Each ring has six carbon brush contact; 9-10 is TGP-OGPCom. Data signals, each ring has six carbon brush phase: 11-12 is OGP-TCPCom. Data signals, each ring has six carbon brush phase. The metal ring arranged of RF slip ring is the same with SHDCD, but the brush material is a metal, the number of brush also less (a total of 16 power brush, 24 signals brush).

There are two slip ring structures of Hispeed CT machine. One for SHDCD slip ring, the other for the RF slip ring, there are differences between the brush plate structure of these two slip rings, brush shapes, materials and quantities are different. Each conductive ring has a number of brushes with phase, which is to ensure good contact and reduce the voltage drop. SHDCD slip ring from the inside out, from 1 to 3 ring 480V power supply, each ring has nine carbon brushes phase; 4-5 ring is 115V power supply, each ring has 5 carbon brush contact; 6 ring is ground GND, There are six carbon brush phase; 7-8 is a trigger signal DAS. Each ring has six carbon brush contact; 9-10 is TGP-OGPCom. Data signals, each ring has six carbon brush phase: 11-12 is OGP-TCPCom. Data signals, each ring has six carbon brush phase. The metal ring arranged of RF slip ring is the same with SHDCD, but the brush material is a metal, the number of brush also less (a total of 16 power brush, 24 signals brush).

4.The slip ring failure:

Spiral CT fast rotational speed, therefore also faster brush wear, worn powder is likely to cause poor contact slip rings. If longer dirty, it will generate a lot of sparks when working, the slip ring surface burn rough, aggravated damage slip ring, causing serious bad, so CT machine failure rate increased, shortening the life of CT machine. Spiral CT is a precision medical equipment, expensive. Therefore, slip ring maintenance is very important.

5. The slip ring maintenance procedures:

1) Normally, slip ring maintenance should be carried out within three months, if the workload, you can shorten the time between maintenance.

2) Before maintenance slip ring, off the PDU, CB5 (slip ring 115V switch), wait five minutes, after the high-pressure part of the fully discharged, then starting maintenance.

3) ROTATE gantry rotation base 1 after the switch is off, demolition gantry cover.

4) Loosen the brush plate before fixing screws, first around the screw marked. So that after the maintenance is installed correctly.

5) Disconnect the brush board signal connector CNI, then remove the brush plate.

6) Check the brush wear indicator, if the wear has reached the mark, should be replaced with new carbon brushes.

7) With a vacuum cleaner and brush clearing brush and brush block, be careful not to touch the brush and slip ring, because oil will affect the contact brushes and slip rings.

8) Clean the slip ring and the surrounding area.

9) Fitted cover, turn the rotating gantry base after a switch, turning DPU box CB1, CB5.

10)Tube heating program, and then scan once, confirm each part of the machine is working properly.

The life of the slip ring and brush with the rotation, and therefore the number of scan rotations should be recorded after each maintain, also recorded bulb impressions, and make maintenance records to facilitate future reference.

About:

Cosmau design and manufactures slip ring and rotary union for a wide range of industry applications. Cosmau's products provide reliable transfer of signal, power, fluid and gas from stationary to a rotating structure.

For more details about slip ring, please http://www.arslipring.com/products.html